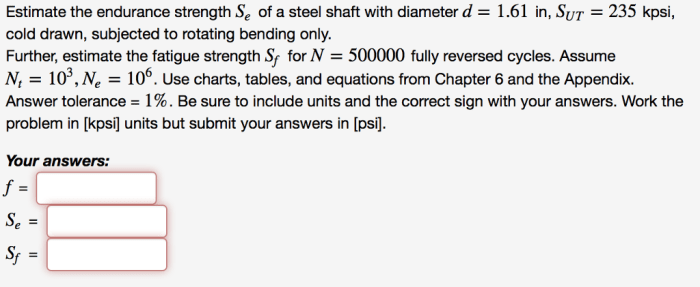

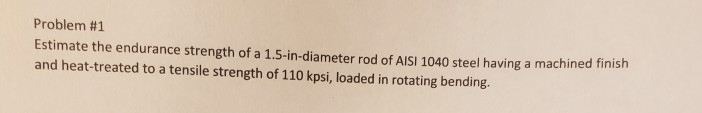

Estimate the endurance strength of a 1.5 in diameter – The endurance strength of a material is a critical factor in determining its ability to withstand repeated loading and deformation without failure. In this article, we will explore the concept of endurance strength, examining the material properties, loading conditions, design considerations, testing methods, and applications that influence it.

We will delve into the significance of yield strength, ultimate tensile strength, and other material properties, as well as the effects of cyclic loading, fatigue loading, and impact loading on endurance strength.

We will also discuss the role of stress concentration, surface finish, and geometric features in optimizing endurance strength. Various testing methods, including fatigue testing and impact testing, will be described, along with their advantages and limitations. Finally, we will explore real-world applications where endurance strength is a critical factor, highlighting its importance in ensuring the safety, reliability, and performance of various components and structures.

Material Properties

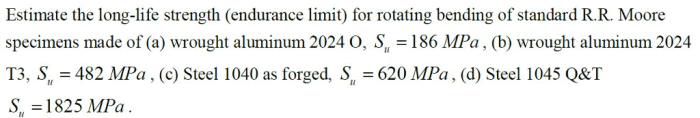

Material properties play a crucial role in estimating the endurance strength of a material. Yield strength, ultimate tensile strength, and fatigue strength are some of the key material properties that influence endurance strength.

Yield strength represents the stress at which a material begins to deform plastically. Ultimate tensile strength, on the other hand, is the maximum stress a material can withstand before it fractures.

Fatigue strength is a measure of the material’s ability to resist repeated or cyclic loading. It is typically lower than the ultimate tensile strength and is a critical factor in applications where the material is subjected to fluctuating loads.

Loading Conditions

Loading conditions significantly impact the endurance strength of a material.

- Cyclic loadinginvolves repeated application and removal of load, leading to fatigue failure.

- Fatigue loadingrefers to repeated loading below the yield strength, which can cause crack initiation and propagation.

- Impact loadinginvolves a sudden and high-magnitude force, which can cause brittle failure.

Understanding the type of loading condition a material will experience is crucial for accurate endurance strength estimation.

Design Considerations, Estimate the endurance strength of a 1.5 in diameter

Design factors also influence the endurance strength of a component.

- Stress concentrationoccurs at geometric discontinuities, such as holes or notches, and can amplify the local stress, reducing endurance strength.

- Surface finishaffects the initiation and propagation of cracks. A rough surface finish can act as a nucleation site for cracks, reducing endurance strength.

- Geometric features, such as the shape and size of the component, can influence the stress distribution and, consequently, the endurance strength.

Optimizing these design factors can improve the endurance strength of a component.

Testing Methods

Various testing methods are used to evaluate the endurance strength of materials.

- Fatigue testinginvolves subjecting a specimen to repeated cyclic loading until failure occurs. The number of cycles to failure provides an indication of the material’s fatigue strength.

- Impact testingmeasures the energy absorbed by a specimen during a sudden impact load. The absorbed energy can be used to estimate the material’s impact strength.

Selecting the appropriate testing method depends on the specific application and the type of loading condition the material will experience.

Applications

Endurance strength is a critical factor in numerous applications.

- Automotive components, such as crankshafts and connecting rods, are subjected to cyclic loading and require high endurance strength.

- Aerospace structures, such as wings and fuselages, must withstand fatigue loading due to repeated takeoffs and landings.

- Medical implants, such as bone screws and joint replacements, need to endure repeated loading without failing.

Accurate endurance strength estimates are essential for ensuring the safety, reliability, and performance of these applications.

Common Queries: Estimate The Endurance Strength Of A 1.5 In Diameter

What is endurance strength?

Endurance strength is the ability of a material to withstand repeated loading and deformation without failure.

What factors influence endurance strength?

Material properties, loading conditions, design considerations, and testing methods all influence endurance strength.

Why is endurance strength important?

Endurance strength is important because it ensures the safety, reliability, and performance of components and structures that are subjected to repeated loading.