A rope under a tension of 200 n – When a rope is placed under a tension of 200 N, it undergoes a fascinating interplay of forces and stresses that shape its behavior. This article delves into the physical properties, tension dynamics, and safety considerations associated with ropes under tension, providing a comprehensive understanding of this essential component in various applications.

As we explore the intricacies of a rope under 200 N tension, we will uncover the factors that influence its performance and the practical implications of these principles in real-world scenarios.

Rope Properties

Ropes are versatile tools with a wide range of applications, from construction and engineering to sports and recreation. Their physical properties, such as flexibility, strength, and elasticity, make them suitable for various purposes.

Flexibility refers to the ability of a rope to bend or conform to different shapes without breaking. It is crucial for ropes used in applications where maneuverability is essential, such as climbing, sailing, or tying knots.

Strength

Strength is a critical property that determines the load-bearing capacity of a rope. It is measured by the amount of force required to break the rope. Ropes used in high-stress applications, such as towing, lifting, or securing heavy objects, must have sufficient strength to withstand the imposed loads.

Elasticity

Elasticity refers to the ability of a rope to stretch under load and return to its original length when the load is removed. This property is particularly important for ropes used in dynamic applications, such as bungee jumping or shock absorption systems.

The elasticity of a rope determines its ability to absorb energy and reduce the impact of sudden forces.

Tension

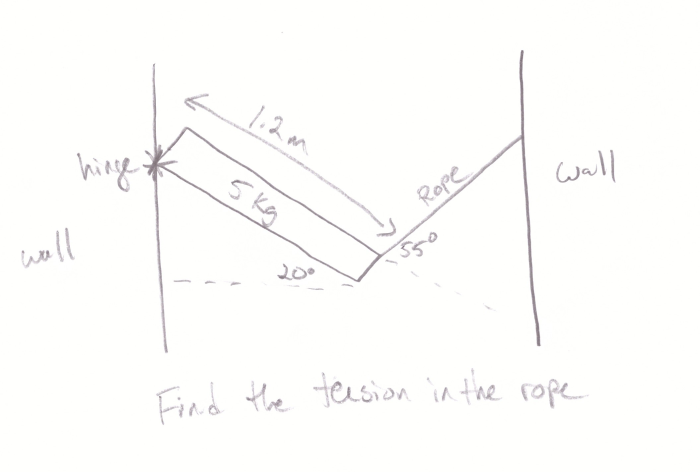

Tension is the force that acts along the length of a rope or other flexible material when it is pulled tight. It is measured in newtons (N), which is the SI unit of force. One newton is equal to the force required to accelerate a mass of one kilogram at a rate of one meter per second squared.

The tension in a rope is caused by the forces acting on it. These forces can include the weight of the object that the rope is supporting, the force of the person pulling on the rope, and the force of gravity.

The tension in the rope is equal to the sum of these forces.

Factors Affecting Tension

The tension in a rope is affected by several factors, including:

- The weight of the object that the rope is supporting

- The force of the person pulling on the rope

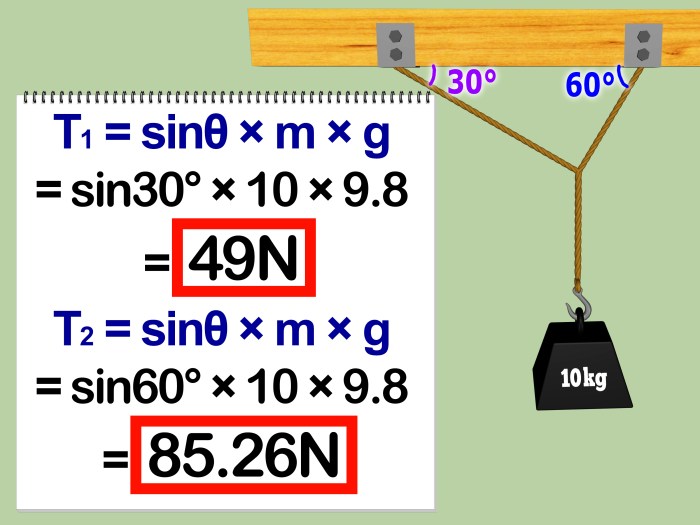

- The angle at which the rope is pulled

The weight of the object that the rope is supporting is the most important factor that affects the tension in the rope. The heavier the object, the greater the tension in the rope.

The force of the person pulling on the rope also affects the tension in the rope. The harder the person pulls, the greater the tension in the rope.

The angle at which the rope is pulled affects the tension in the rope. The smaller the angle, the greater the tension in the rope.

Force and Stress

In the context of a rope under tension, force, and stress are closely related concepts. Force refers to the external force applied to the rope, while stress is the internal force per unit area that resists deformation.

The tension in the rope is the force that is applied to it, pulling it in opposite directions. This tension creates stress within the rope, which is the force per unit area that resists the deformation caused by the tension.

Stress-Strain Relationship, A rope under a tension of 200 n

The relationship between stress and strain is known as the stress-strain curve. For a rope, the stress-strain curve is typically linear up to a certain point, known as the yield point. Beyond the yield point, the rope begins to deform plastically, and the stress-strain curve becomes nonlinear.

A rope under a tension of 200 N can withstand a considerable amount of force. If you’re looking for a reliable resource to help you understand mathematical concepts related to this topic, consider checking out the Saxon Math 6/5 Answer Key PDF . It offers a comprehensive set of solutions to guide you through your studies.

Returning to the topic of tension, a rope under a tension of 200 N can be used in various applications, such as lifting heavy objects or creating a secure anchor point.

The slope of the stress-strain curve is known as the Young’s modulus, which is a measure of the stiffness of the rope. A higher Young’s modulus indicates a stiffer rope that is more resistant to deformation.

Effects of Tension on Rope Performance

The tension in a rope can have a significant impact on its performance. Excessive tension can cause the rope to stretch, weaken, or even break. It is important to ensure that the tension in a rope is within the safe working load of the rope to avoid damage or failure.

Safety Considerations

Working with ropes under tension requires strict adherence to safety precautions to prevent accidents and injuries. It is crucial to properly inspect and maintain ropes to ensure their safe use.

Regular inspections should be conducted to identify any signs of damage or wear. This includes checking for cuts, fraying, or any other abnormalities that could compromise the rope’s integrity.

Proper Rope Handling

- Avoid overloading ropes beyond their specified working load limit.

- Use proper knots and techniques to secure ropes and prevent slippage.

- Protect ropes from sharp edges or abrasive surfaces.

- Store ropes in a dry, well-ventilated area away from sunlight and extreme temperatures.

Applications: A Rope Under A Tension Of 200 N

Ropes under tension have a wide range of applications in various industries and everyday life. They are commonly used in situations where it is necessary to transmit force, secure objects, or provide support.

The principles of tension and stress play a crucial role in determining the suitability and effectiveness of ropes for specific applications. Tension refers to the force applied along the length of the rope, while stress is the force per unit area experienced by the rope material.

Lifting and Hoisting

Ropes under tension are extensively used in lifting and hoisting operations. In cranes, elevators, and construction equipment, ropes are employed to lift and lower heavy loads. The tension in the ropes must be carefully controlled to ensure the safe and efficient operation of the equipment.

Marine Applications

In the marine industry, ropes are essential for mooring, anchoring, and towing vessels. The tension in the ropes must be carefully managed to prevent damage to the vessels or the ropes themselves. Synthetic ropes, such as nylon and polyester, are commonly used in marine applications due to their high strength and resistance to water damage.

Safety and Recreation

Ropes are also widely used in safety and recreational activities. In rock climbing, ropes provide a lifeline for climbers, ensuring their safety in case of a fall. In sports like tug-of-war, the tension in the rope is the primary force that determines the outcome of the competition.

FAQ Corner

What factors affect the tension in a rope?

Tension in a rope is influenced by the weight of the object it supports, the angle at which it is pulled, and the material properties of the rope.

How can I ensure the safe use of ropes under tension?

Regularly inspect ropes for damage, use proper knots and hitches, and avoid exceeding the rope’s rated capacity.

What are some real-world applications of ropes under tension?

Ropes under tension are used in construction, rigging, rock climbing, sailing, and many other applications where lifting, securing, or suspending objects is required.